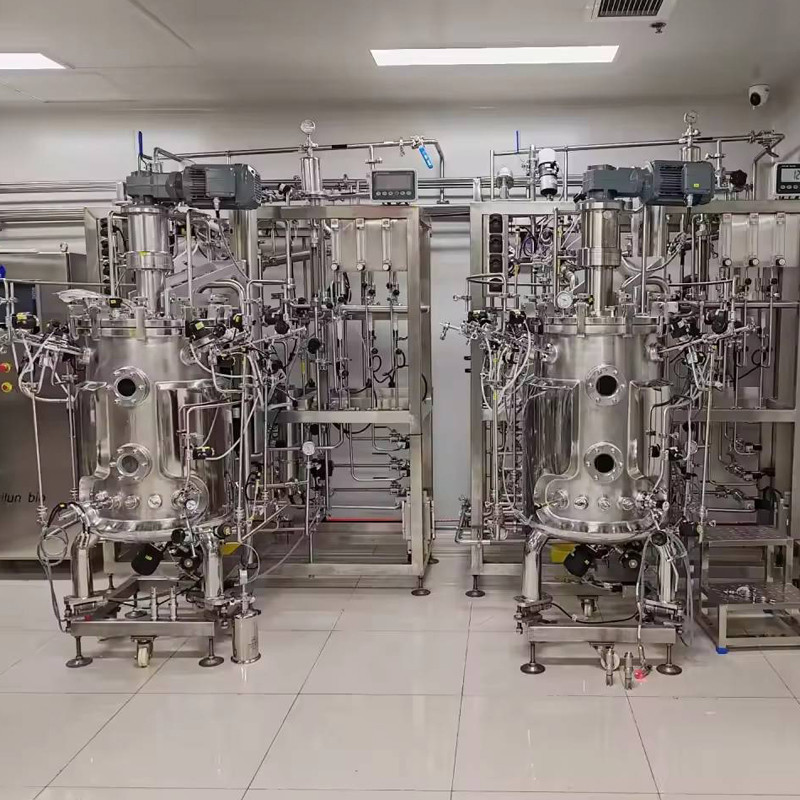

Bioreactor, Bacteria, and Stainless Steel Fermenter

- Share

- Issue Time

- Jun 30,2024

Question 1: What is a bioreactor and how does it work?

A bioreactor is a device or system that provides a controlled environment for biological processes to occur. It is designed to support the growth, metabolism, and production of various biological entities, such as cells or microorganisms. The bioreactor regulates parameters like temperature, pH, oxygen supply, nutrient availability, and waste removal to optimize the desired biological reactions.

Question 2: How are bacteria utilized in a bioreactor?

Bacteria can be cultivated in a bioreactor for several purposes. They can be used for the production of valuable metabolites like antibiotics, enzymes, or organic acids. Bacteria can also be employed in bioremediation processes to break down pollutants. Additionally, they can be engineered to express specific proteins or perform specific functions for various applications.

Question 3: Why is stainless steel commonly used in the construction of fermenters?

Stainless steel is preferred for several reasons. It is highly resistant to corrosion, ensuring the longevity and integrity of the fermenter even when exposed to harsh chemicals and sterilization processes. It is easy to clean and sterilize thoroughly, reducing the risk of contamination. Stainless steel also provides good mechanical strength and durability.

Question 4: What types of stainless steel are suitable for bioreactor and fermenter construction?

Typically, grades such as 304 and 316 stainless steel are commonly used. Grade 316 is often chosen when there is a higher risk of corrosion or when the bioreactor will be exposed to more aggressive chemicals.

Question 5: How is the growth of bacteria monitored in a bioreactor?

This can be done through various methods. Regular sampling and analysis of the culture can provide information on cell density, metabolic activity, and product formation. Sensors can also be installed to monitor parameters such as pH, dissolved oxygen, and substrate consumption in real-time.

Question 6: What safety measures should be considered when operating a bioreactor with bacteria?

It is crucial to ensure proper sterilization of the equipment to prevent contamination and the spread of harmful bacteria. Workers should follow strict biosafety protocols, including the use of personal protective equipment. The bioreactor should also have pressure relief valves and other safety features to prevent overpressure or other hazardous situations.

Question 7: How is the quality of the final product from a bacterial bioreactor ensured?

This is achieved by maintaining consistent and optimal operating conditions throughout the process. Stringent quality control measures, such as regular testing and analysis of the product, are implemented. Adhering to good manufacturing practices and regulatory standards is also essential.

Question 8: Can different types of bacteria be cultivated simultaneously in the same bioreactor?

It is possible, but it requires careful consideration of the compatibility of the bacteria in terms of their growth requirements and potential interactions. Separate compartments or controlled conditions might be needed to prevent competition or negative effects on each other's growth.

Question 9: How often does a stainless steel bioreactor need to be maintained and serviced?

The frequency depends on factors such as the frequency of use, the nature of the process, and the specific design of the bioreactor. Regular inspections, cleaning, and component checks should be conducted. Typically, major servicing might be required every few months to a year.

Question 10: What are the challenges in scaling up a bacterial culture from a laboratory-scale bioreactor to an industrial-scale fermenter?

Some challenges include maintaining uniform conditions throughout the larger volume, ensuring efficient mass and heat transfer, and managing the increased complexity of control systems. Changes in shear stress and oxygen distribution can also affect bacterial growth and productivity.

Question 11: How is the oxygen supply optimized for bacterial growth in a bioreactor?

This can be achieved through proper aeration systems, such as spargers or bubble columns. The agitation speed and design also play a role in distributing the oxygen evenly within the culture. Monitoring the dissolved oxygen level and adjusting the aeration and agitation accordingly is important.

Question 12: Can a used stainless steel bioreactor be repurposed for a different bacterial process?

It can be, but it requires thorough cleaning, sterilization, and possibly modification depending on the new requirements of the process. It is important to ensure that there are no remnants of the previous process that could interfere with the new one.

Question 13: How do environmental factors affect bacterial growth in a bioreactor?

Environmental factors like temperature fluctuations, changes in pH, and the presence of impurities in the nutrients can have significant impacts on bacterial growth and metabolism. These factors need to be closely monitored and controlled to maintain optimal conditions.

Question 14: What are the latest technological advancements in bioreactor and fermenter design for bacterial cultures?

Advancements include the integration of advanced sensors for more accurate monitoring, the development of more efficient agitation and aeration systems, and the use of smart control algorithms for automatic process optimization.

Question 15: How is energy consumption managed in a stainless steel bioreactor for bacterial processes?

This can be achieved through efficient design of the agitation and aeration systems, optimizing the temperature control, and using energy-efficient components. Regular assessment and improvement of the overall energy efficiency of the bioreactor are important for sustainable operation.