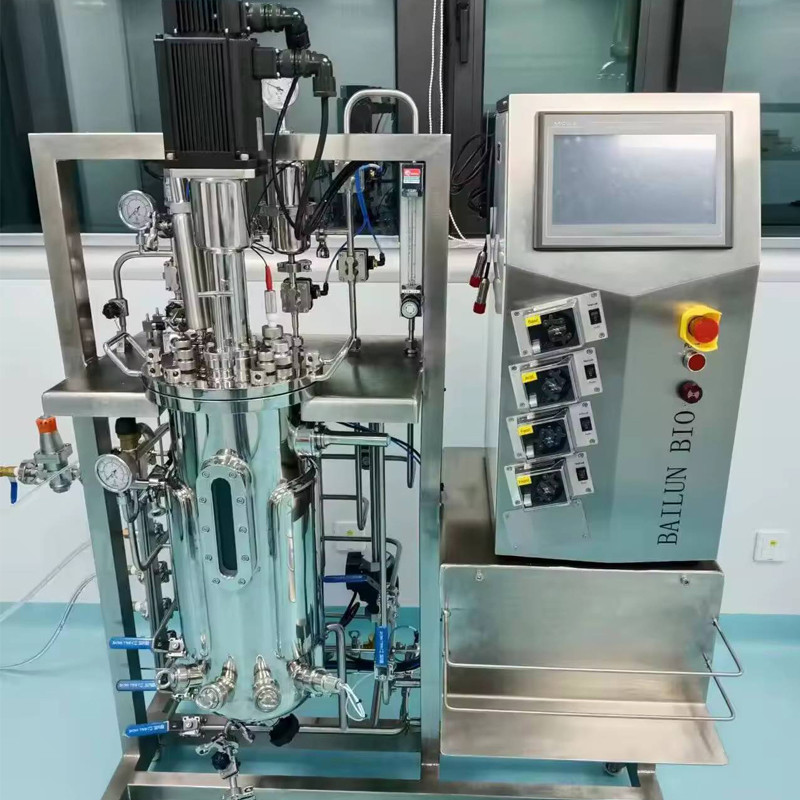

Cell Culture Bioreactor, Cells Bioreactor, Mini Lab Bioreactor

- Share

- Issue Time

- Jul 12,2024

Question 1: What is a cell culture bioreactor?

A cell culture bioreactor is a device designed to provide a controlled environment for the growth and maintenance of cells in vitro. It allows for precise regulation of parameters like temperature, pH, oxygen levels, and nutrient supply to support cell proliferation and function.

Question 2: How does a cells bioreactor differ from a regular cell culture flask?

A cells bioreactor offers more advanced control and monitoring capabilities compared to a simple cell culture flask. Bioreactors can regulate multiple parameters simultaneously and often have systems for continuous medium exchange, aeration, and agitation, which are not typically present in a standard flask.

Question 3: What are the benefits of using a mini lab bioreactor?

Mini lab bioreactors are compact, cost-effective, and take up less space in the laboratory. They are suitable for small-scale experiments, pilot studies, and initial optimization of cell culture conditions. They also provide more controlled and reproducible conditions than traditional methods.

Question 4: Can a mini lab bioreactor be used for all types of cell cultures?

Mini lab bioreactors can be used for a wide variety of cell cultures, including mammalian cells, microbial cells, and plant cells. However, the suitability depends on the specific requirements of the cell type and the objectives of the experiment or process.

Question 5: How do I maintain sterility in a cell culture bioreactor?

To maintain sterility, you need to ensure proper cleaning and sterilization of the bioreactor before use. All components that come into contact with the cells and culture medium should be autoclaved or treated with appropriate sterilizing agents. During operation, aseptic techniques should be strictly followed when adding or removing samples or media.

Question 6: How often do I need to change the culture medium in a bioreactor?

The frequency of medium change depends on the cell type, growth rate, and the metabolic activity of the cells. It can range from a few days to several hours and is typically determined based on monitoring parameters like nutrient depletion and metabolite accumulation.

Question 7: Can I scale up from a mini lab bioreactor to a larger industrial-scale bioreactor?

Yes, data and parameters obtained from mini lab bioreactor experiments can be used as a basis for scaling up to larger bioreactors. However, additional considerations and optimizations are necessary to account for differences in fluid dynamics, mass transfer, and heat transfer at larger scales.

Question 8: What kind of monitoring is possible in a cell culture bioreactor?

Common monitoring parameters include cell density, viability, pH, dissolved oxygen, metabolite concentrations, and temperature. Advanced bioreactors may also allow for real-time monitoring of gene expression, protein production, and other molecular markers.

Question 9: How do I troubleshoot if my cell culture in the bioreactor is not growing as expected?

Possible causes could include incorrect parameter settings (e.g., temperature, pH, oxygen), contamination, nutrient deficiency, or improper cell seeding density. Checking and validating the instrument's functionality, performing sterility tests, and analyzing the culture medium composition can help identify and address the issue.

Question 10: What safety precautions should I take when working with a cell culture bioreactor?

Always wear appropriate personal protective equipment (PPE) like gloves, goggles, and lab coats. Be familiar with the operation manual and safety guidelines of the bioreactor. Ensure proper electrical grounding and handle chemicals and biological materials safely to prevent exposure and accidents.