Cell Culture Bioreactors: Revolutionizing Cell Growth and Research in the Laboratory

- Share

- Issue Time

- Jul 12,2024

Summary

Cell Culture Bioreactors: Revolutionizing Cell Growth and Research in the Laboratory

In the dynamic landscape of modern biological research and biotechnology, cell culture bioreactors have emerged as indispensable tools that have transformed the way cells are grown, studied, and manipulated. This article explores the world of cell culture bioreactors, with a focus on their types, functions, and the significant impact they have on various scientific and industrial applications.

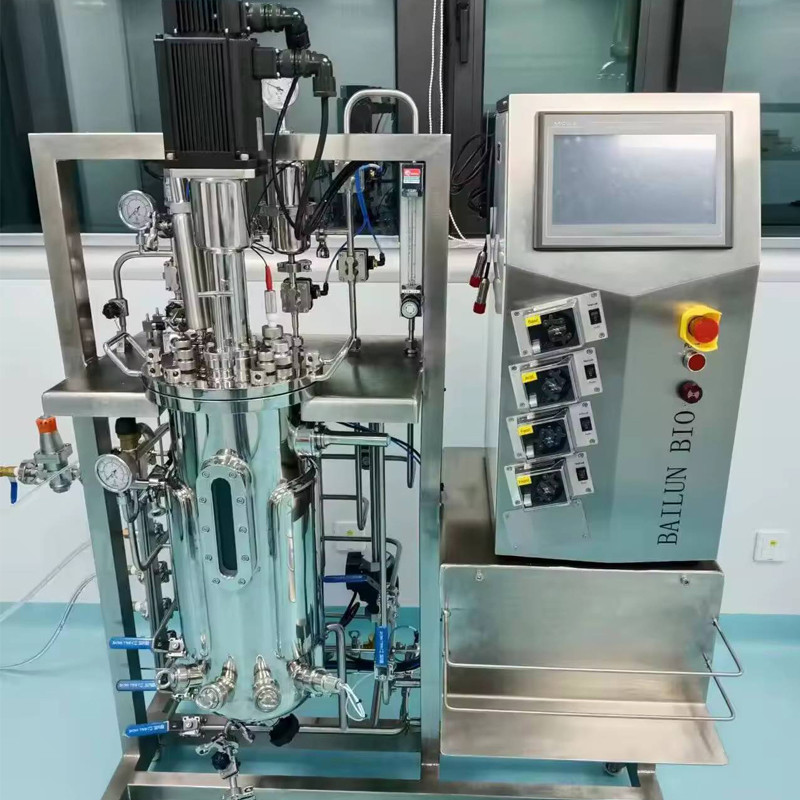

The cell culture bioreactor is a sophisticated device designed to create an artificial environment that closely mimics the natural conditions required for cell growth and proliferation. These bioreactors provide a controlled and regulated space where cells can thrive and carry out their metabolic processes efficiently.

One of the primary types of cell culture bioreactors is the mini lab bioreactor. These compact and versatile systems are ideal for laboratory-scale research and experimentation. Mini lab bioreactors offer several advantages in a research setting. Their small size makes them highly accessible and manageable within the confines of a laboratory bench. Despite their reduced dimensions, they are equipped with advanced features and capabilities that allow for precise control and monitoring of the cell culture environment.

The design of a mini lab bioreactor incorporates various components and mechanisms to ensure optimal cell growth conditions. Temperature control is a crucial aspect, as cells have specific temperature ranges within which they function optimally. Mini lab bioreactors are equipped with heating and cooling elements that maintain a stable and precise temperature throughout the culture process.

pH regulation is another critical factor in cell culture. Cells require a specific pH level for enzymatic activities and overall metabolic processes. The bioreactor is fitted with pH sensors and systems that enable the automatic adjustment of the pH by the addition of appropriate buffers or acids and bases.

Oxygen supply is essential for the survival and growth of many cell types, especially those that are aerobic. Mini lab bioreactors incorporate aeration systems that supply the necessary oxygen to the cells. Additionally, agitation mechanisms ensure the uniform distribution of oxygen and nutrients throughout the culture medium, preventing the formation of gradients and ensuring that all cells have access to the essential substances they need for growth and metabolism.

The use of mini lab bioreactors extends beyond basic cell culture. They are invaluable tools in the study of cell behavior, drug screening, and the development of new therapeutic strategies. For example, in drug discovery, these bioreactors can be used to culture cancer cells and test the efficacy of potential anti-cancer drugs.

By precisely controlling the culture conditions and monitoring the response of the cells to the drug treatment, researchers can gain valuable insights into the mechanism of action of the drugs and their potential therapeutic applications.

In addition to mini lab bioreactors, larger-scale cell culture bioreactors are used in industrial and clinical applications where large quantities of cells or cell-derived products are required. These systems are designed to handle higher volumes of cell cultures and are often equipped with automated control and monitoring systems to ensure consistent and reliable performance.

Cells bioreactors, in general, play a crucial role in the field of regenerative medicine. Stem cells, which have the potential to differentiate into various cell types, can be cultured and expanded in bioreactors to generate sufficient cell numbers for therapeutic applications such as tissue engineering and cell-based therapies. In tissue engineering, cells are seeded onto scaffolds and grown in bioreactors under controlled conditions to form functional tissues and organs.

Another important application of cell culture bioreactors is in the production of biopharmaceuticals. Antibodies, vaccines, and other therapeutic proteins can be produced by culturing mammalian cells in bioreactors. The controlled environment provided by the bioreactor helps to ensure the high-quality and consistent production of these biomolecules, which are crucial for the treatment of various diseases and medical conditions.

The development and advancement of cell culture bioreactor technology are constantly evolving.

New materials and designs are being explored to improve the biocompatibility and performance of the bioreactors. The integration of sensors and microfluidic devices within the bioreactor systems allows for real-time monitoring and manipulation of the cell culture environment at a single-cell level, opening up new frontiers in cell biology research.

In conclusion, cell culture bioreactors have become an integral part of modern biological research and biotechnology. From the small-scale mini lab bioreactors used in fundamental research to the large-scale industrial bioreactors used in the production of biopharmaceuticals and regenerative medicine applications, these devices have revolutionized the way cells are grown and studied.

As technology continues to advance, cell culture bioreactors will undoubtedly play an even more significant role in shaping the future of healthcare, drug discovery, and tissue engineering, leading to new and innovative treatments and therapeutic strategies.