Amplification of fermentation process

- Share

- Issue Time

- Feb 11,2025

Summary

parallel bioreactor systems

1. Overview

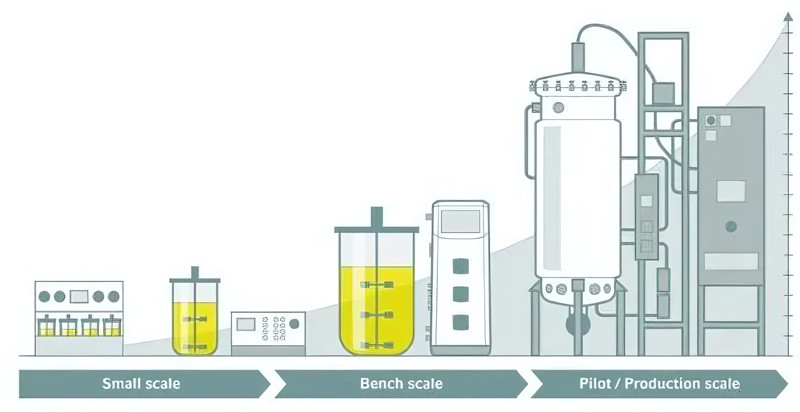

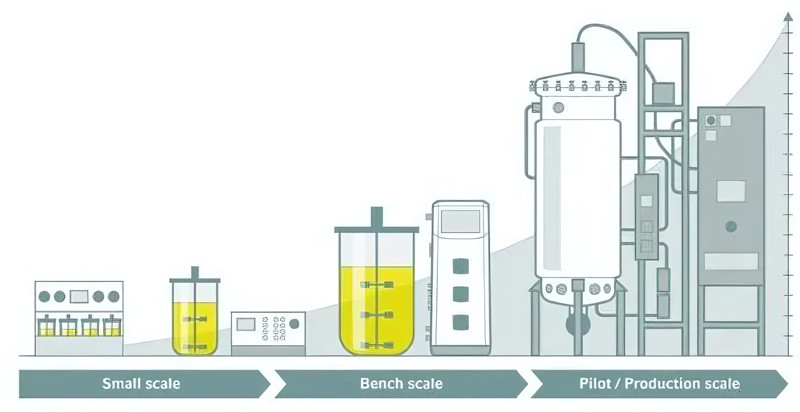

Scale down: Large scale fermentation production conditions are used as small and medium-sized experimental conditions.

Scale up: Apply laboratory and pilot plant results to large-scale fermentation industries.

2. Key factors for zooming in or out

Analysis of environmental conditions for small and large devices (as consistent as possible)

Chemical factors: matrix, precursor concentration, etc., can be kept constant by human control;

Physical factors: temperature, bacterial concentration, viscosity, pressure, power consumption, shear force, etc.

3. The process of amplification

The first stage involves laboratory scale screening of bacterial strains and research on culture media.

In the second stage, the scale of the pilot plant will be determined to determine the optimal operating conditions for bacterial culture.

The third stage is large-scale production in factories.

4、 Principles and guidelines for scaling up bioreactors

The ideal reactor amplification should achieve similar conditions:

1. Geometric similarity

2, fluid mechanics similarity

3, thermodynamic similarity

4, mass (concentration) similarity

5, biochemical similarity

The principle of amplification in bioreactors - similarity principle

If the biochemical reaction processes, fluid flow and momentum transfer, heat and mass transfer processes of the experimental reaction system and the amplification reaction system can be described by the same differential equation and have the same characteristics, then the two systems have the same behavior.

5、 Scaling up methods for bioreactors

· Experience amplification method

· Zoom in/out method

· dimensional analysis method

· Mathematical modeling method

6、 Design of Ventilated Fermentation Tank - Empirical Amplification Method

1、 Geometric similarity amplification

Enlarge according to the geometric dimensions of each component of the reactor. The magnification factor is actually the increase factor of the reactor.

2、 Constant equal volume stirring power amplification

This method is suitable for biological fermentation controlled by dissolved oxygen rate, non Newtonian fluids with high viscosity, or cultures with high cell density.

3、 Constant volume dissolved oxygen coefficient amplification

This method is suitable for scaling up reactors for Newtonian fluids and high oxygen consuming fermentation processes (bacterial fermentation, yeast fermentation).

4、 Constant stirring blade tip linear velocity amplification

Suitable for amplifying fermentation processes in which biological cells are significantly affected by agitation and shearing, such as the fermentation of filamentous bacteria. The tip velocity (π Dn) of the stirring blade is the key factor determining the stirring shear strength.

5、 Constant mixing time amplification

Mixing time refers to the time required to add materials to a reactor until they are evenly mixed. In small reactors, it is easier to mix evenly, while in large reactors, it is more difficult.

6、 Air flow amplification

(1) Enlarge based on the principle of equal air flow rate per unit volume of culture medium (2) Enlarge based on the principle of equal linear air flow rate (3) Enlarge based on the principle of equal KLa value